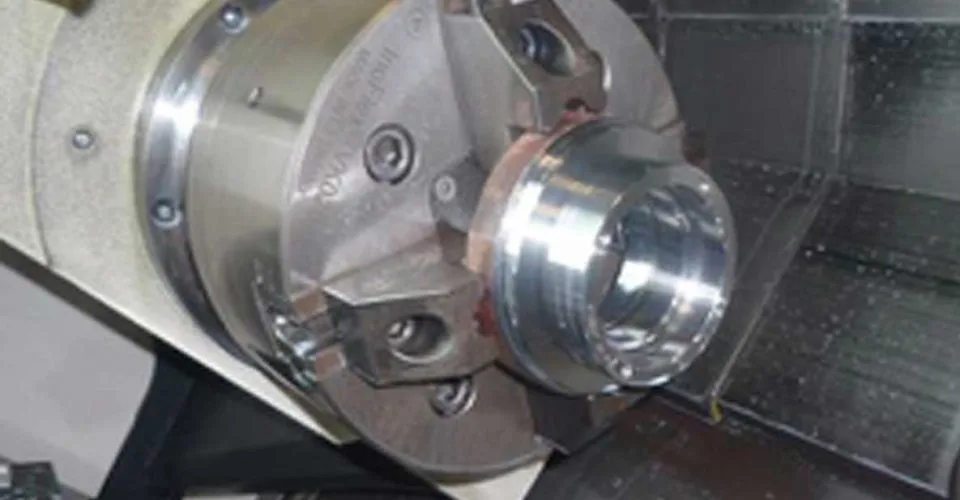

Use of INOFlex® chuck ensures fewer concentricity deviations

Drive technology manufacturer improves dimensional accuracy in the bearing seat.

Traditional chucks quickly reveal their limitations when producing parts with irregularities or asymmetrical shapes. Traditional 3-jaw chucks are rarely well-suited for clamping angular structures, and non-compensating 4-jaw chucks are disadvantaged by static over-determination – not all jaws fit. As a result, these irregular parts cannot be centrically clamped.

STÖBER Antriebstechnik GmbH & Co. KG faced this dilemma when machining thin-walled asymmetrical parts. An electronic, motor and gear manufacturer, STÖBER found that the high clamping pressure of 2- and 3-jaw chucks resulted in large concentricity deviations. When it began searching for alternative solutions, its attention was drawn to the [InoFlex] chuck from HWR Workholding. The 4-jaw chuck features compensating centric clamping, meaning that the opposing jaws approach the workpiece in pairs. This ensures that components are centrically clamped and that all jaws grip with the same gripping power.

The unique design of the [InoFlex] chuck makes the workpiece shape irrelevant, so there is no need for parameters to be adjusted for different castings. Increasing the number of clamping points from three to four also significantly improved part concentricity. The new chuck enabled STÖBER to improve product quality while also shortening the set-up and clamping times.

Gears, motors and geared engines have been made at STÖBER’s HQ in Pforzheim for many decades. Various cast blanks are turned and milled onsite. In recent years, the company has realized there was an opportunity to optimize its turning operations.

“Up to last year we used traditional 2 and 3-jaw chucks for turning cast and forged blanks”, says Volker Manz, Head of Production at STÖBER. “The drawback was that they had to be re-set following a nest change due to certain differences between the cast batches.”

This resulted in a marked lengthening of the machining time per batch. Additionally, and especially with asymmetrical and thin-walled blanks, there was often a problem with the jaws not gripping properly. Consequently, excessive clamping pressure had to be used for fail-safe clamping. This frequently caused deformations and concentricity deviations.

FOUR DIAMETRICALLY COMPENSATING CHUCKS FOR MORE FLEXIBILITY

“My colleagues from central technology planning became aware of HWR Workholding’s [InoFlex] from reading trade journals and reported this to me”, explains Mr. Manz. “We thought the concept was convincing and wanted to test it in use.”

As a result, STÖBER contacted HWR. Following a presentation in Pforzheim and intensive consultations, chucks were constructed on the basis of a workpiece drawing. Following delivery, STÖBER tested [InoFlex]’s performance.

“We monitored the test series for the first two days”, remarked Peter Pott, sales staff member at HWR Spanntechnik GmbH.

[InoFlex] met STÖBER’s expectations, providing flexibility with only minor deformation. In contrast to traditional chucks for lathes, [InoFlex] is equipped with four jaws. They ensure not only better holding, irrespective of the shape of the workpieces, but also far less polygonal deformation.

“We gave ourselves the assignment in 2010 of devising a clamp that grips both the circular and cubic geometries and the asymmetrical parts”, recalls Volker Henke, managing director at HWR. “Our aim was also to optimize the gripping power, rotational speed, overall height and weight in order for them to be compared with a commercially available 3-jaw chuck.”

It quickly became apparent that four jaws were required to provide adjustment to all possible part shapes, though the problem of physical over-determination still remained. When all jaws move evenly to the center, force cannot be reduced at a single point. The innovative solution to this challenge was compensating clamping technology. With it, both jaw pairs can rest independently of each other – yet centrically – against the workpiece.

REDUCTION DOWN TO JUST NINE COMPONENTS

As the first [InoFlex] prototypes contained 60 components, the need for further optimization was clear. The final result is assembled from just nine parts. The two diametrically opposed jaw pairs are driven by a link gear. With the reduction in components and corresponding minimization of abrasion, the patented [InoFlex] can hold its own against 3-jaw chucks.

The [InoFlex] VK031 deployed at STÖBER is a closed power chuck that provides a 9.6 mm lift, maximum 182 kN gripping power and rotational speed of 2,800 per minute. Gripping power of up to 230 kN is possible with other models in the line. Thanks to the flexible mounting, [InoFlex] can be fitted in lathes, milling machines and combined machines.

“An important point for us was the possibility of using it in various machines”, explains Mr. Manz. “Various jaw shapes should also be fittable.”

By incorporating four jaws, [InoFlex] significantly reduces deformation and provides a high true running precision were also obtained. Re-run precision is also improved.

SHAPE PRECISION CLEARLY ENHANCED

There was a marked rise in quality of the STÖBER final products with only a slight deformation in clamping the workpieces, even with asymmetrical blanks.

“In particular, shape precision in the bearing seat is now clearly greater – it is around 6 μm and above”, says Mr. Manz. “Furthermore, differences between the blanks no longer play a role and parametrizations when changing the cast nests are unnecessary. This has allowed the entire process to be optimised from operation through process reliability up to the final result.”

To ensure a long service life, HWR uses to high-grade and well-finished materials. All parts are hardened and then hard-machined or ground. In addition, all clamping devices are FEM-calculated and thus are non-fatigue-critical.

“We also test all our clamping devices for fatigue strength on our own test bench”, says Mr. Henke.

STÖBER is also convinced of the top quality involved. Two [InoFlex] chucks are now in operation in the company’s mechanical manufacturing section and a quote for a third model has already been drafted.