Since 1989 HWR has grown from a design office to an innovative manufacturer of clamping devices in metal working establishing itself in the market.

HWR Workholding USA are specialists in clamping deformation-sensitive workpieces and in compensating, concentric clamping of components of any shape. Your application in focus: With more than 30 years of experience, we know your applications exactly – and always focus on your requirements in our developments. At HWR the power of innovation meets absolute precision in execution. The result: application-optimized clamping devices that reliably meet the increasing demands in turning operations. Rely on effective and low-cost solutions for optimal production results.

Careers at HWR

There are no vacancies available at the moment.

-

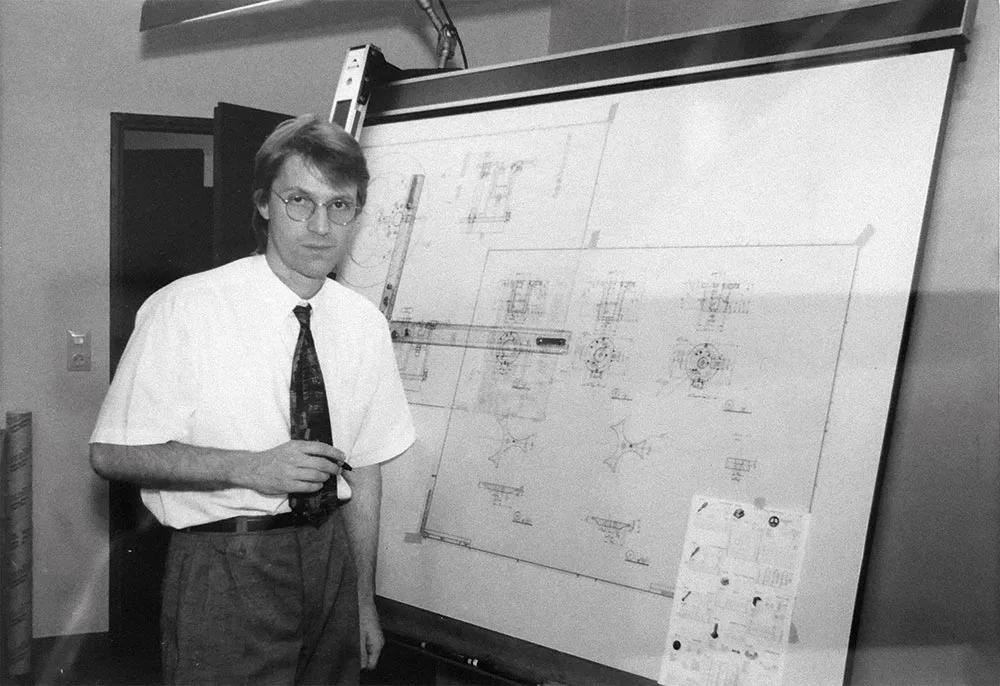

1989

HENKE MANUFACTURING FACILITY FOUNDED

In the beginning, mechanical equipment and small manufacturing solutions were developed in the home of Volker Henke’s parents. The new company grew through its projects and employees. Soon the company moved to its own facility in order to expand.

-

1990

START OF SALES AND DISTRIBUTION OF CLAMPING JAWS

At the end of 1990 HWR became the nationwide German representative for Thame Workholding clamping jaws. The company’s customer base grew over time throughout Germany, concentrating in Northern and Central Germany.

-

1995

PRODUCT RANGE EXPANDED

Successive expansion of the product range with manual and power chucks and customised designs. First own field sales representatives in NRW and Hamburg.

-

1997

EXPANSION OF THE PRODUCTION FACILITY AND SALES

Continuous expansion of sales, design and manufacturing. New building and expansion of the company’s building in Oyten.

-

2003

PARTNERSHIP WITH LANG TECHNIK

Development of the INOGrip® stamping jaw system in cooperation with LANG Technik. Commencement of sales in Northern and Central Germany for LANG Technik products. Turntec Award presented to the company in Frankfurt at EuroMold.

-

2009

DEVELOPMENT AND LAUNCH OF THE INOZet® CLAMPING SYSTEM

INOZet® transforms a 3-jaw chuck into a compensating 6-jaw chuck. The clamping system is showcased at NORTEC in Hamburg and wins the NORTEC Award.

-

2011

DEVELOPMENT OF THE INOTop® HYBRID CLAMPING JAW

Development and launch of the INOTop® clamping system – a hybrid clamping jaw developed by HWR, which centres workpieces from the outside and clamps them from the inside.

-

2013

DEVELOPMENT OF THE INOFlex® CLAMPING SYSTEM

Development and launch of the INOFlex® clamping system – a compensating 4-jaw chuck developed by HWR.

-

2014

EXPANSION OF THE MANAGEMENT

Henrico Viets and Matthias Meier join the management team.

-

2015

MOVE INTO THE NEW OFFICE BUILDING

The new and bigger office building as well as larger production and storage space offer possibilities for new product developments and enhancements.

-

2016

DEVELOPMENT OF THE WEIGHT OPTIMISED INOFlex® TYPE VL

The product range was expanded by the weight optimised INOFlex® type VL for milling-turning centres.

-

2018

INTRODUCING INOFlex® VFA, THE FIRST AUTOMATION CLAMPING DEVICE BY HWR

The 1,500th INOFlex® chuck was delivered. More and more customers rely on the compensating clamping technology. 42 patents granted worldwide.

-

2019

INTRODUCTION OF THE NEW VT-S CHUCK SERIES

Presentation of the new zero-point and clamping technology series SOLIDline at the EMO in Hanover. Inclusion in the DMQP program of DMG MORI. INOFlex® chucks can now be ordered directly with a machine via DMG Mori. The location in Oyten is extended by approx. 1,000 m2 production.

-

2022

HWR EMPOWERS AMERICAN MANUFACTURING

HWR Workholding USA is created. A warehouse is established in central Indiana. The company provides HWR products and support to the United States and Canada.