Always Properly Centered and Balanced

Through HWR’s INOFlex and INOZet clamping solutions, EMB Zerspanungstechnik further enhanced its ability to meet customers’ quality demands.

EMB Zerspanungstechnik (translated, EMB Machining Technology) was founded in Beidenkopf, Germany in 1955. The area, including nearby Lahntal, was well known for its foundries, and EMB started as a foundry producing hearth and furnace castings.

Currently in its third generation of leadership, the company is headed by managing partner Michael Runkel and employs 17 people. In 1973, EMB transitioned from foundry to machine shop, and it acquired its first CNC machine in 1986. Today, it operates twelve CNC machines for turning and milling.

Most commonly, EMB machines parts from spheroidal castings of grey cast iron. The company also manufactures parts from both aluminum and stainless steel, predominantly 1.4305.

“Most of our customers are foundries and engine plants, along with others from agricultural technology, bearing technology and the fitness industry”, says Mr. Runkel of EMB’s customer base.

Approximately 80% of the components produced by EMB are turned parts, ranging from 20 mm to 300 mm in diameter and weighing up to 14 kg. Lot sizes can run from 200 to 30,000 pieces. The company has noted a significant increase in the demand for milled features in recent year, leading it to adopt CNC turn mills with 5-axis machining capabilities. EMB also provides customers with subassembly mounting.

“In our assembly department, we assemble, for instance, some 50,000 sub-assemblies each year for a major customer,” explains Mr. Runkel. “These, as completely picked & packed merchandise, are supplied with all accessories directly to the customers.”

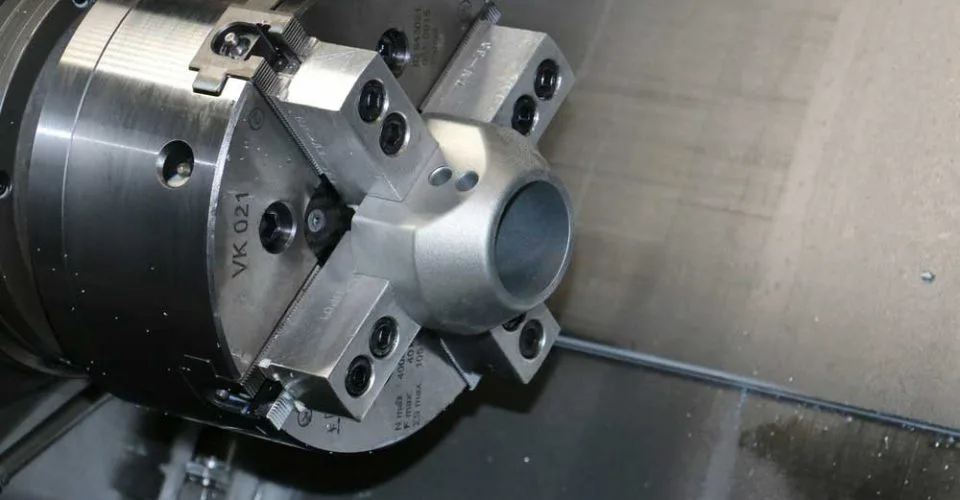

EMB first started using HWR products in 2015, when it purchased the INOFlex® compensating, four-jaw chuck. This compensating chuck provides centric clamping of round, rectangular and irregularly shaped workpieces.

“We had received an inquiry from a customer on machining aluminum components,” says Mr. Runkel. “One of these components recalled to mind an advertisement from HWR for the INOFlex® chuck. After a thorough examination, we decided to opt for this chuck as it promised ease in clamping the component.”

EMB uses the INOFlex® chuck on an INDEX G200 CNC turn mill. Currently, two parts that are nearly identical in design are being produced on the machine.

“The parts are components for supporting arm systems,” says Mr. Runkel. “The INOFlex® is the ideal clamping solution since the parts have two straight and two semi-circular surfaces. The part could not be properly clamped in a three-jaw chuck.”

Optimal clamping is of vital importance, as they are zinc die-cast parts with extremely high tolerances. EMB finds exceptional value in INOFlex®’s ability to center parts correctly at all times.

Dennis Richter from HWR’s Technical Sales team has worked with EMB since 2016, having been assigned to the company’s region at that time. He consulted with the company when one of its customers requested production of a high-precision component requiring cylindricity within a tolerance of 6 microns. Reviewing the part drawing together, Mr. Richter and Mr. Runkel agreed that the HWR INOZet® clamping system was likely the best solution.

INOZet® pendulum bridges allow traditional 3-jaw chucks to be quickly and easily converted into compensating 6-jaw chucks. The increased points of contact prove a tremendous advantage when machining thin-walled components.

“We had to look into whether these specific tolerances could be held by the INOZet® system,” says Mr. Richter. “It is difficult to guarantee a cylindricity of six microns, but we believed it could be done and proceeded with testing the solution.”

It quickly became apparent that the system was capable of producing the part to the required specifications.

“Set up. Part manufactured. Part finished,” recalls Mr. Runkel. “It was quick and simple, as was intended. The INOZet® is a great product and functions perfectly.”

Today, when EMB encounters jobs with thin-walled parts that are experiencing deformation with a 3-jaw chuck, it quickly employs INOZet®. The system’s advanced capabilities have allowed the company to meet increasingly stringent demands from customers, while retaining flexibility and profitability.