“Almost Continuously in Operation”

Flexible enough to meet changing demands and precise under pressure: this the guiding philosophy of PräziTec Haustein GmbH. The metal processing company from Tettnang on Lake Constance performs turning, milling, grinding and multi-task processing on a wide variety of parts for customers spanning a diverse range of industries.

In June 2018, the company implemented HWR Workholding’s INOFlex® 4-jaw-chuck for concentrically and compensating clamping of workpieces. The product has met PräziTec’s exacting requirements, both in terms of precision and flexibility.

Partner for “special tasks”

In 1995, brothers Andreas and Michael Haustein, together with their father Horst, founded PräziTec in Friedrichshafen on Lake Constance. Their first customers included ZF Friedrichshafen, the world’s second largest automobile supplier, and MTU, a part of Rolls-Royce Power Systems AG. Other well-known mechanical engineering companies supported PräziTec at the beginning in offsetting capacity peaks. Geographical proximity kept the logistics manageable.

Rapid growth increased the demand for more new machines, on the company needed additional space. The Hausteins moved to nearby Tettnang two years after the firm was founded. Ten years later, in 2007, the addition of a new manufacturing bay enabled further growth.

In the meantime, the regular customers of the family-run company have become more diversified. The high-precision manufactured parts are used, for instance, in vehicle and utility vehicle construction, mechanical engineering, medical technology and aviation. PräziTec routinely works with cast iron, steel, stainless steel and aluminum. Production parts up to 220 mm in diameter can be produced in batches of up to 150,000 pcs. The company also produces large parts in batch sizes ranging from 1 to 150.

According to Managing Director Andreas Haustein, the company’s first-class technical equipment provides a unique advantage, enabling a broad manufacturing range between 65 and 1,200 mm diameters.

“We have machines which hardly any supplier has, allowing us to take perform a wide variety of metal-cutting processes – something our customers very much appreciate”, says Mr. Haustein.

PräziTec has always followed the philosophy of ensuring a high level of compatibility between its machines, tools and clamps to ensure highly flexible operations.

“We can very efficiently turn, mill and drill highly complex parts on our multi-task machines, all in one clamping operation”, he explains. “Unproductive set-up times rarely exist.”

A chuck for almost everything: INOFlex VL120

The INOFlex® VL120 chuck from HWR plays a major role in PräziTec’s operations. Measuring 1,150 mm in diameter, the patented all-purpose clamp reliably secures round, rectangular and geometrically misshaped workpieces from 160 to 1,200 mm diameters. This ability – which no other clamp on the market offers – is something that PräziTec has learned to appreciate, particularly when turning a round component on a square blank.

“The clamp has been almost continuously in service since it was bought last year. With it, we cover 85% to 90% of the large parts”, says Mr. Haustein. “INOFlex® has practically replaced a vice for us. We can directly clamp components with the chuck which otherwise would have been machined by way of a fixture.”

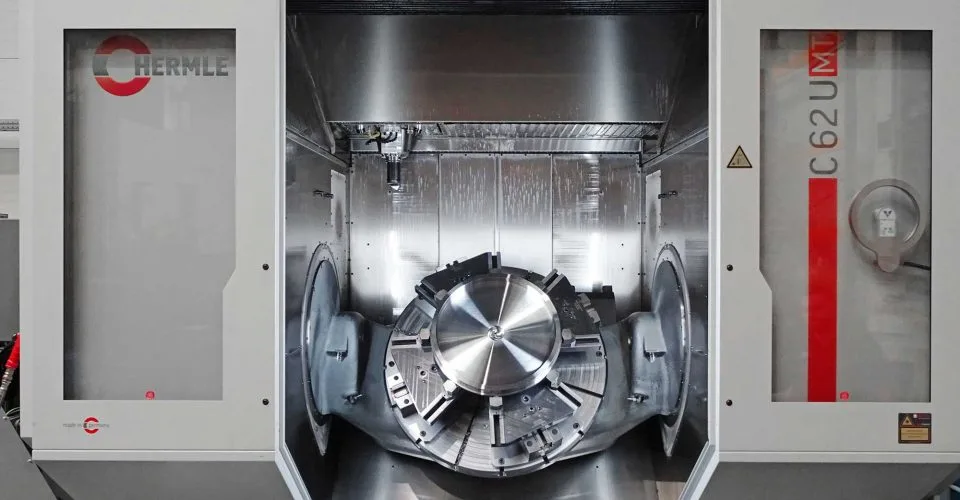

The 4-jaw centering clamp was acquired together with a new multi-task machining centre, a Hermle C62 MT, which is now the largest machine at PräziTec. When Mr. Haustein was evaluating the machine, he saw it operating with the INOFlex® VL120 chuck – a combination that impressed him.

PräziTec – embracing precision technology at every level

When it comes to precision, PräziTec places exacting demands on its equipment, as can be seen by glancing into the company’s manufacturing bay. The modern multi-task machines have a measuring function which determines the quality of the workpiece during machining. But this alone is not good enough for the Hausteins.

“The findings can be quickly distorted by surrounding conditions”, explains Mr. Haustein. “That is why we have a measurement chamber with a ZEISS CNC 3D-coordinate measurer complete with scanning. It allows us to examine even large components, up to 1,200 mm, in a much more precise manner.” This is how he describes the benefits of the instruments which contribute decisively to quality assurance. “As such, we can handle tolerances up to H5.”

“We want our stock of machines to be state-of-the-art at all times”, says Mr. Haustein. This is the only way the company can ensure consistent high product quality, given the enormous diversity of part sizes, shapes and materials.

INOZet®-pendulum bridges for perfect concentricity

With INOZet®, the Hausteins have a true ace up their sleeves, especially when it comes to machining deformation-susceptible and misshaped components. The patented pendulum bridges from HWR Spanntechnik have been integrated with the INOFlex® chuck and the CNC machining centre – an investment which Andreas Haustein is not likely to regret. In particular, when machining thin-walled, round workpieces, he appreciates the advantages of the pendulum bridges.

“We use them mainly for flange-like components”, says Mr. Haustein. Doubling the clamping points from four to eight makes a decisive difference. The improved distribution of clamping force and shortening of the exposed gaps results in a marked reduction of component deformation. As a result, the company is able to produce first-class parts with immaculate concentricity.

The INOZet® pendulum bridges have also proved durable and reliable. The pendulum mechanism is protected against dirt and can be cleaned quickly and easily, as Andreas Haustein emphasises: “All you need is to clean the supporting points”, he explains. The pendulum bolts are then optimally protected from dirt-induced wear. The system eliminates the need to acquire innumerable customized clamping jaws over the long-term, as – together with a set of standard clamping jaws – the INOZet®-pendulum bridges cover the entire clamping range and can be retrofitted at low cost at any time.

Machine operator Thomas Walther is also aware of how well his workplace is equipped: “The machine with the large chuck and the pendulum bridges – this puts us in a completely different league”, he concludes.